We all love the way an embossed feature on a printed piece adds texture and highlights areas that warrant additional focus. Understanding the options that are readily available will allow you to select the best fit to enhance your print design.

Emboss vs. Deboss

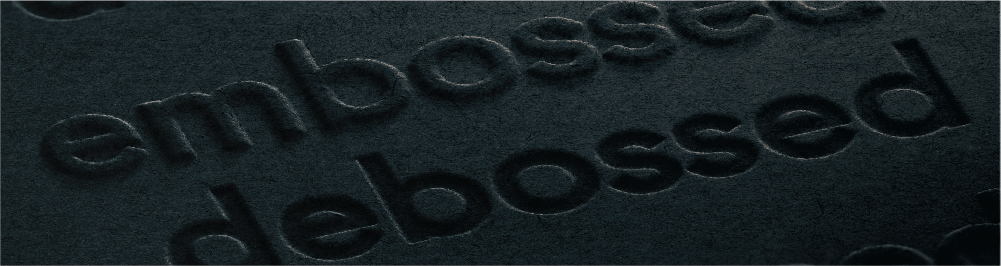

The first decision that needs to be made is about the effect you are hoping to achieve with this technique. Although most of us talk about embossing for texture, there is also the option of debossing. How are they different? Very basically, an embossed feature is raised against the background; a debossed feature is sunken into the substrate. Both can be used in combination with offset printing and foil stamping to add that extra “pop” to your design.

The depth of emboss (or deboss) will depend on the effect you are hoping to achieve and thickness of your paper. This should be reviewed with your printer as part of your job prep to ensure that the desired effect can be attained on the stock you have selected. A significant impact can be attained with as little as a 15 mil emboss. Heavier embossing can be done but may require a more intricate die. For more embossing tips, visit the Graphic Designer’s Guide to Embossing.

Types of Dies

So, let’s talk about your options. Dies can range from very basic to very complex and will produce different results. Many options are available. A few of the most common are noted below.

1. Single-level – As the name implies, this die will change the paper surface at a single level (up or down – depending on if you emboss or deboss). This technique is appropriate for fairly simple designs. This is the most common type of emboss and dies can be relatively inexpensive.

2. If you are looking for significant height in your emboss you should consider a beveled edge die. Beveled-edge dies have a bevel on the image edges that allows for embossing without cutting the paper.

3. Multi-level dies have a number of distinct levels. They create additional texture and the varied depths further enhance images. In combination with printing or foil, multi-level dies can bring an image to life!

4. Sculptured dies are probably my favorite. Of course, I have expensive taste (so I’ve been told). These dies are generally hand tooled and made of brass. They emboss on many levels and include curves, angles and other fine details. One of my favorite examples of this was in the Domtar promo – Saddle Up with Lynx, where we offset printed, used a sculptured emboss, and then flocked an image of a bull. Not only is the image “fuzzy”, but you can “feel” the folds and texture of his skin under the flocking.

Embossing can be tailored to match the desired aesthetic of your design. Work with your printer to determine the best (and most cost effective) way to achieve the effect you are hoping for.

Lori is the Technology Manager for Domtar’s Printing Papers grades. Also known as the printing fairy, she spends a lot of time in pressrooms making sure Cougar, Lynx Opaque Ultra and Husky consistently meet end use performance expectations. With a focus on grade specifications and product design, Lori is keeping her eye on developing technologies and new applications for printing papers. When not focused on “the right fiber” for making paper, Lori is busy growing herbs and hot peppers for making the perfect salsa and chili.

Blog retrieved from Domtar Blueline